MVR Evaporator

Reactor based

working principle

Are you tired of cleaning your Evaporator Heat Exchanger frequently due to choking?

Are you facing the issue of High Running Cost of Operation of the Evaporator?

Are you Fed up of providing Continuous Steam to the Evaporator and to the Dryer?

Are you frustrated of Additional High Drying costs after the Effluent is discharged from the Evaporator?

Introducing our

MVR Evapo-Concentrator

What is MVR Evapo-Concentrator ?

An MVR Evapo-Concentrator is a combination of an MVR Evaporator and a Concentrator. The MVR Evaporator uses the MVR Technology to recover heat and Evaporate the Effluent. The Concentrator further concentrates the Effluent till the point where all salts present in the Effluent precipitates completely.

This helps in easy separation of Salts from the water content resulting into Cheaper and Easier Drying process.

MVR Concept

MVR technology is the latest trend available in the market for treatment of Industrial Effluents. Lombardyne has incorporated Mechanical Vapour Recompressor ( MVR ) Technology to reduce the operating cost of the Evaporator. The MVR Technology uses the principle of Latent Heat Recovery which is released by the Effluent during Evaporation.

During Evaporation process, a major portion of Energy is released in the form of Latent Heat. This Latent heat has a substantial amount of Energy. In COnventional Evaporators, this Latent Heat is released to the Cooling tower thus wasted to the atmosphere. In MVR Evaporators, the same Latent Heat is recovered back to feed to the remaining Effluent. Thus no External Heat is required. Obviously the major running cost of the Evaporator is due to the Latent Heat. Due to the MVR Technology, Lombardyne Evaporators successfully recover all the Latent Heat released by the Effluent and feeds it back to the remaining Effluent. This substantially reduces the operating cost as no External Heat is required to maintain the Effluent temperature and Evaporate the Effluent.

Concentrator Concept

Concentional MVR Evaporators available in the market have Calandria Heat Exchangers incorporated in their design. Due to the Calandria Heat Exchanger, these Evaporators have to be stopped just before the Salts in Effluent precipitates or else the Calandria Heat Exchanger gets clogged. Lombardyne MVR Evaporators DO NOT use Calandria but instead have specially designed Reactor based Spiral Tube Heat Exchangers. Due to this, all our Evaporators can successfully Concentrate the Effluent at much higher levels where the Effluents get completely precipitated inside the Evaporator yet without choking.

The advantage of having an Evaporator combined with a Concentrator can also be termed as MVR Evapo-Concentrator.

It enables the customer to adopt simpler and Cheaper options for drying of the Salts.

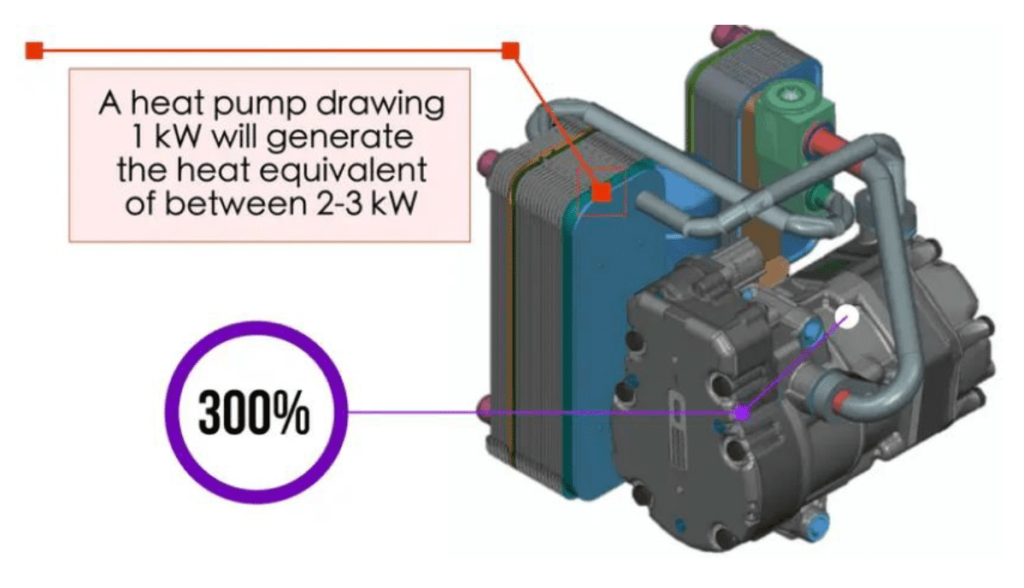

Heat Pump Concept

Lombardyne Evaporators are inbuilt with Heat Pumps for Efficient Heating. Heat Pumps work on the principle of Reverse refrigeration cycle. These Heat Pumps have a High efficient ratio of 1:3 when generating Heat.

Eg. To generate a Thermal Heat capacity of 3 KW, a Heat Pump will utilize only 1 KW of Electrical Energy.

Capacity:

500 LPH - 6000 LPH

Input TDS Range:

1000 - 150000

Output Concentrate:

40% - 60%

Auto Effluent In / Auto Condensate Out / Auto Level Maintain

Advantages

Skid Mounted Unit

( 70% Less Space )

Steam Free Operation ( No Boiler needed )

High Concentration

Low Operating Cost ( 75% reduction )

No Clogging

Easy Auto CIP

How does Heat Pump Vacuum MVR Evaporator work

Main Features

1. Inbuilt Heat Pump Technology ( No External Steam )

No Steam Required

An inbuilt Heat Pump provides all the necessary startup heat to the Evaporator, that too at a fractional cost compared to any conventional Heating source.

2. Reactor type working principle

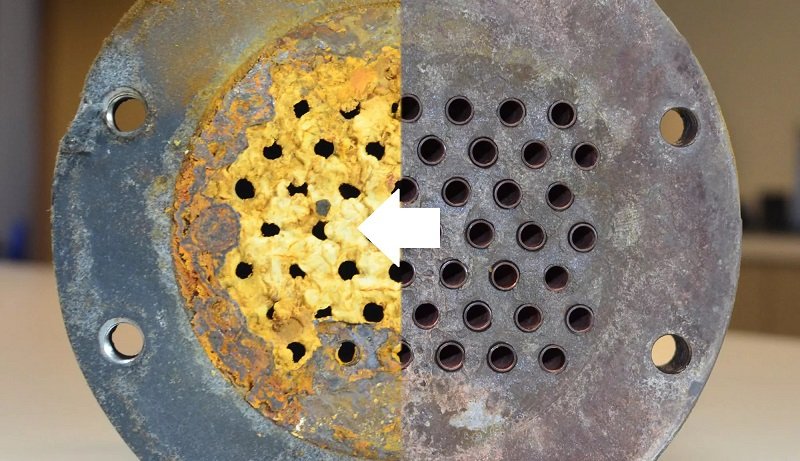

Conventional Evaporators have Calandria Heat Exchangers for Latent Heat Recovery.

Calandria Heat Exchanger is a HE which has multiple vertical Tubes connected sideways. The effluent which consists of various Salts and COD flows through the narrow tubes and whereas the MVR compressed vapour flows outside the tubes.

Generally it is expected that when such Effluents flow from narrow spaces, they tend to choke. This exactly occurs in our conventional Evaporator Heat Exchangers as the effluent frequently chokes inside the Calandria resulting in a breakdown.

Calandria photo

Lombardyne Evaporators DONT use Calandria Heat Exchangers. We have incorporated our Spiral tube Heat Exchanger design which is submerged in a Reactor Vessel with an Agitator installed on top for continuous Mixing. The Agitator circulates the Effluent inside the Vessel and simultaneously outside the Spiral tube Heat Exchanger. Similarly the MVR Compressed Vapour flows inside the Tubes. As the Effluent is outside the Tubes, there is NO scope of choking of the Heat Exchanger. This allows the Evaporator to run without any breakdowns at higher concentration levels.

3. Precipitated Salts Concentrate output

Lombardyne Vacuum Evaporators have implemented innovate spiral tube Heat Exchanger which can concentrate the Effluent at a much higher rate. This can be done without worrying about choking or clogging issues inside the Heat Exchanger.

As our Evaporator can concentrate at a higher rate ranging from 40% to 60%, the Salts present in the Effluent can no longer remain in dissolved form and precipitate.

The precipitated salts are discharged along with water content which further helps the salts disposal. The Precipitated Salts can easily be separated with the help of a Filter press or a Centrifuge.

Precipitated Salt Solution Concentrate

4. Deep Vacuum Technique

Lombardyne Vacuum Evaporators have incorporated deep Vacuum Technique for all our Evaporators.

In this Technique, Deep Vacuum in excess of 700mmHG is applied inside the Evaporator. This enables the Effluent to boil under lower boiling points.

Evaporation under Lower boiling Point enables our Evaporators to condense much higher purity Condensate. Certain COD chemicals present in the Effluent get restricted from carrying over to Condensate and is trapped within the Concentrate due to the advantage of Lower Boiling Point.

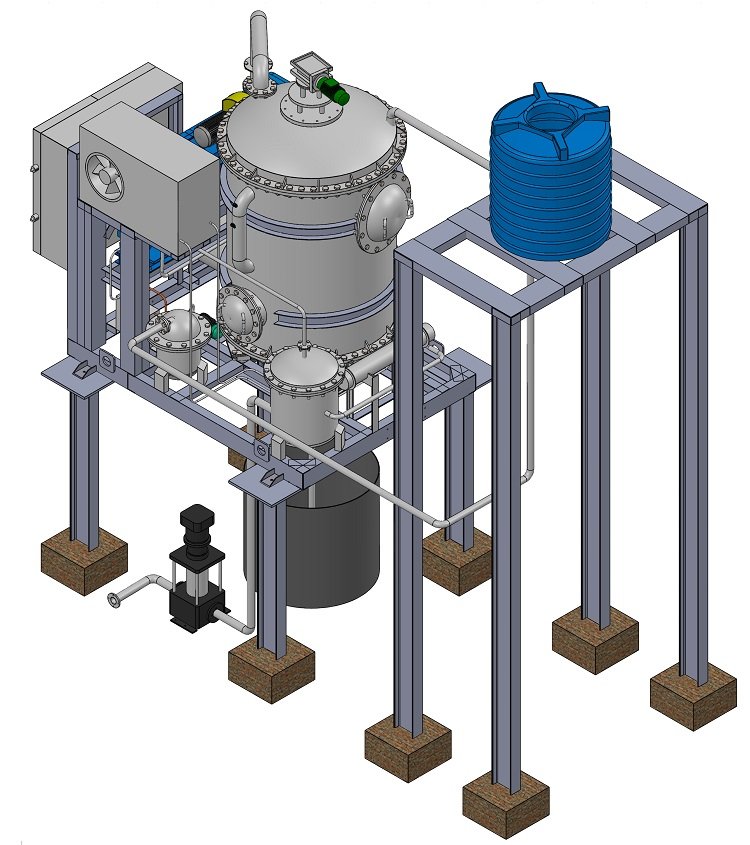

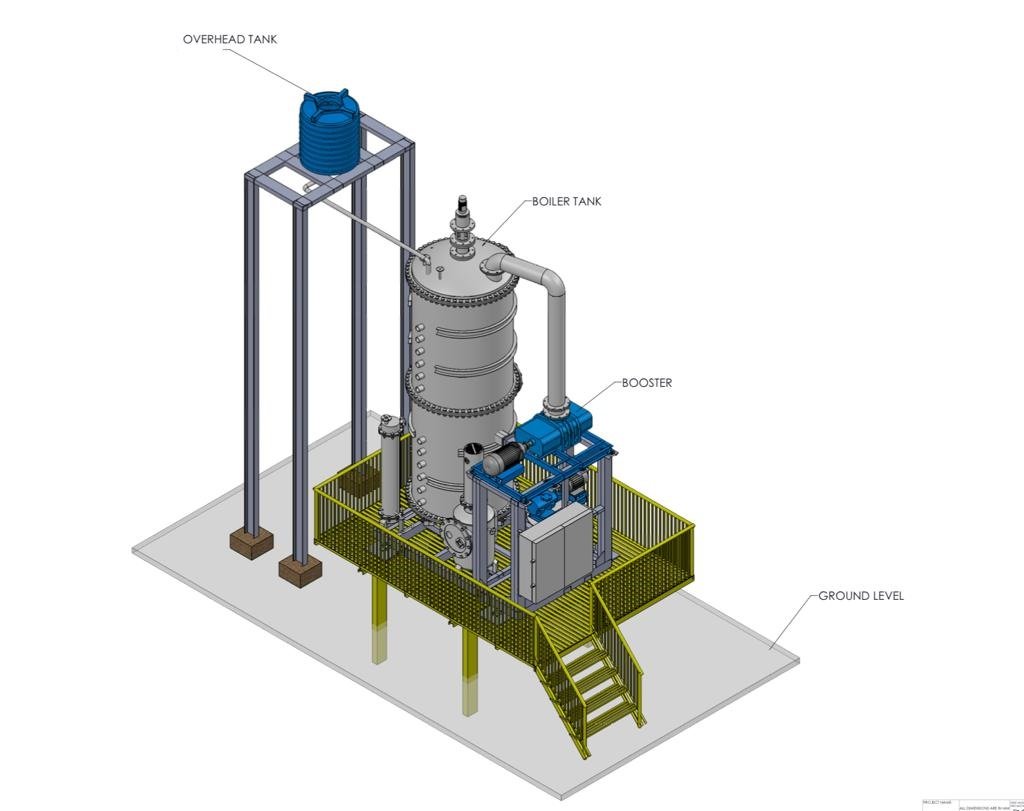

4. Compact Skid Design ( 70% Space Reduction )

Lombardyne MVR Evaporators are completely Skid Mounted and are specially designed for plug and Play type of Installation. As it is a Single Stage Evaporator, it enables the design to be much more compact than the conventional Evaporators.

Due to the incorporation of Spiral Coil Heat Exchanger, it has helped the Evaporator to be much more compact and shorter than the concentional type.

LOMBARDYNE™

INDUSTRIES INDIA PVT. LTD.

The Best in MVR Evaporation Technology

UNIT 1: 123/1, Lane No 11, Ramtekadi Industrial Estate, Hadapsar, Pune 411028

UNIT 2: Plot No 6, Lane No 4, Ramtekadi Industrial Estate, Hadapsar, Pune 411013

+91 8484830943

( Sales / Mktg )

+91 8855013580

( Sales / Mktg )